Lever Servo CalibrationIntroduction

If you have servos that are significantly out of alignment when the robot is in the Calibration Position, the servos may need to be physically calibrated. This process should only need to be done once per servo. This process will require a screw driver to remove the EZ-Clip to realign it at 90 degrees. It's an easy process that should only take a few minutes. When a lever servo needs calibrating, it will not align into the position demonstrated in this document. A non-calibrated lever servo will be angled (not flat/straight) when connected to the EZ-B in calibration mode (90 degree setting). If the lever is angled, that means you will use a screw driver to manually realign the lever bracket. The instructions to realign the bracket are included in this document. What You Will Need

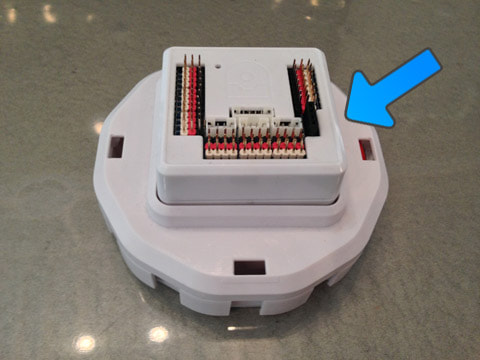

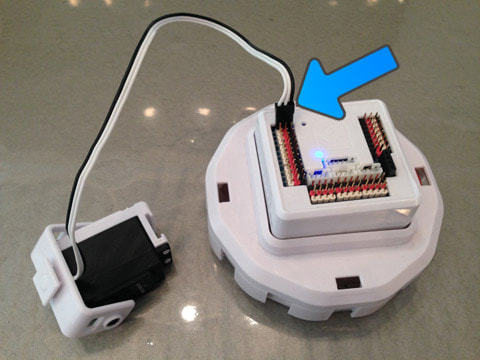

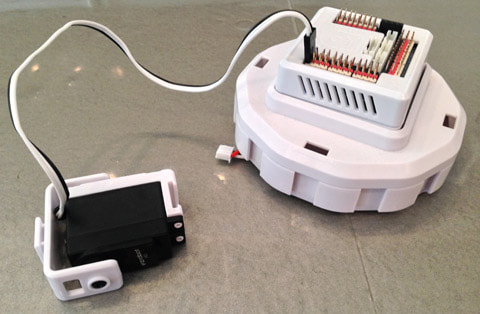

Step 1 Insert the EZ-B v4 Smart Robot Controller into the robot body or powerbase.

Step 2 Turn the power switch to the ON or 1 position. Early EZ-Robots have a power switch labelled ON/OFF, while the newer robots are labelled with a 0/1.

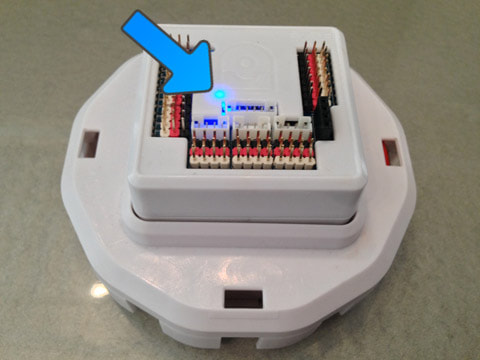

Step 3 When the power switch is turned to the ON position, the EZ-B will be flashing Blue. This means it is ready for a Wi-Fi connection.

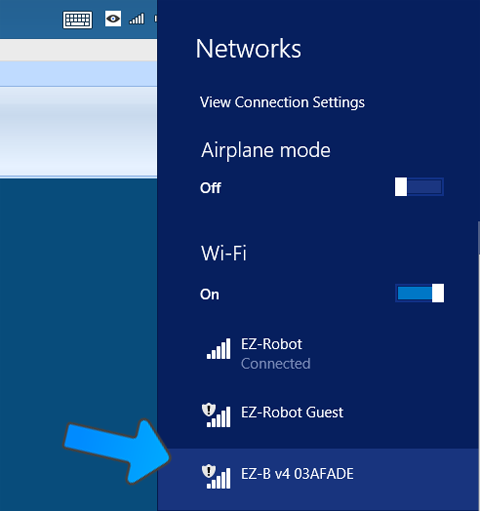

Step 4 Locate the EZ-B Wi-Fi Access Point in your Wi-Fi Networks List. This is accessed by pressing the Wi-Fi button on your system tray.

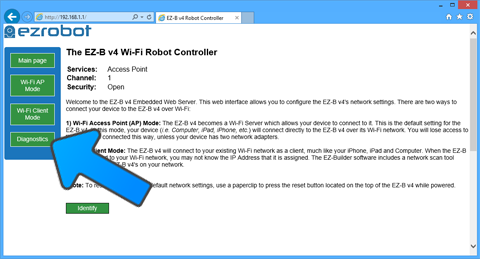

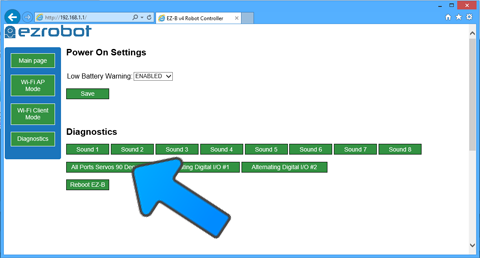

Step 5 Open your web browser and type 192.168.1.1 into the top bar. Press the Diagnostic button from the left side menu.

Step 6 The Diagnostic page will now be displayed. Press the button labelled "All Ports Servos 90 Degrees". This will set all 24 of the digital ports on the EZ-B v4 to 90 degrees. Any servos that are connected to any digital port will now move to what it has been calibrated as 90 degrees. In the next steps, you will see how to calibrate the servo to be aligned at 90 degrees. You will repeat the next steps one at a time per servo.

Step 7 Connect one servo to the EZ-B v4 to view it's calibration position.

Step 8 Once the servo is connected to the EZ-B v4, it will move to what it thinks is 90 degrees. Consult the image above to see what 90 degrees should look like. The lever should be flush with the surface and not angled up or down. Take notice that we use the flat surface of a counter top/table to demonstrate the alignment. You will also use a flat surface when aligning the servos. Do not "eyeball" the alignment - use a flat surface. We will go into further detail in the next steps.

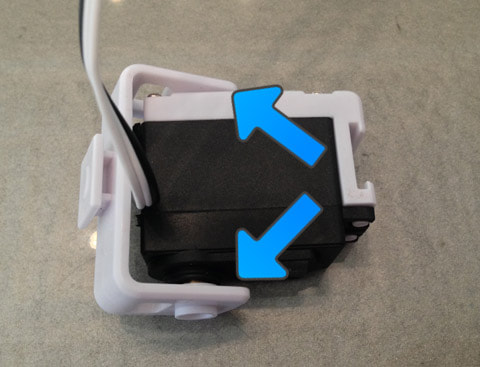

Step 9 After viewing the lever alignment in the previous step, the servo may need calibrating. If the servo needs calibrating, use a Phillips screw driver to remove the screw that holds the lever onto the gear.

Step 10 Now that the screw is removed, you can separate the edges of the lever from the servo to remove it from the servo.

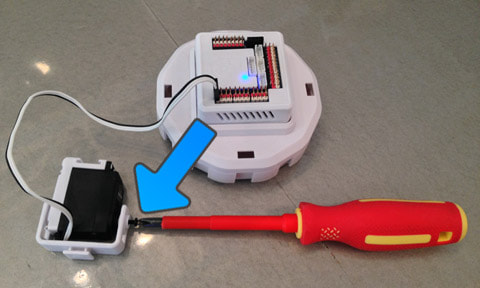

*Note: Do not disconnect the servo from the EZ-B v4 until instructed to do so. Step 11 Slide the lever on the flat surface toward the servo to reconnect. The lever should now be flat (or as much as it can be) with the servo. There are teeth that hold the lever on the servo gear, do not force the lever to be perfectly flat if the teeth do not line up. It is okay if the lever is a little angled by one gear tooth. This can be fine tuned in software if it causes issues with robots requiring high precision, such as JD. In most cases, robots such as Six and Roli do not need very high precision servo calibration.

Step 12 Insert the screw back into the servo gear which holds the lever and tighten it snug. Do not overly tighten, you do not want the screw to dig into the plastic. The strength of the lever from slipping is dependent on the teeth of the gears and not the tightness of the screw.

Repeat and Complete You have now calibrated your servo. Disconnect the servo from the EZ-B v4 and place it with other calibrated servos. You may now repeat this process and calibrate another servo by returning to Step 8.

|